Did you ever realize the air that comes out of the vents in your home? In the winter you may have felt warm air blowing, or cool air in the summer. Ever wonder how that air actually travels from the heating or cooling system to those vents? The solution is something known as a ducting system.

A ducting system is a network of pipes that are designed to convey a gas. These pipes deliver air from the heating or cooling system to various spaces in a structure. The airflow atork through these tubes passes quick and will get out of vents. These are responsible for ensuring the air remains at the proper temperature exactly where you want it to maintain a comfortable warmth in your home.

As an established ducting system consists of several important parts that work together. The first component is referred to as the air handler. The air handler is the main mechanism of a heating or cooling system that moves the air through the ducting system. It’s kind of the heart of the system because it pumps the air where it needs to go.

There are a level of advantages produced from a well-designed and functioning ducting system: This is one of the major benefits as it improves air quality in the house. This allows the air in your home to potentially be more fresh and clean. A ducting system that is working well offers good ventilation, which is required for maintaining healthy air, as we breathe.

One more advantage of proper ducting system is proper air distribution in the building. That means every room receives the proper volume of air, equalizing temperature throughout the entire system. You won’t need to suffer through one room being too hot and another being too cold.

Nonetheless, there are several critical considerations. A danking system will leak air if its design is inappropriate or its installation is done poorly. This occurs when there are gaps or holes in the ducts, causing air to leak. That can allow heated or cooled air to sneak away into the walls or attic or wherever and not make it to the vents. This can cause your heating and cooling system to work harder than normal, and can raise your energy bill.

Plugged ducts can cause problems too. Clogged ducts occur due to the accumulation of dirt, dust, or other materials inside the pipes. This can restrict airflow, preventing air from reaching where it needs to go. If air can’t circulate freely, there can be hot or cold spots in your home.

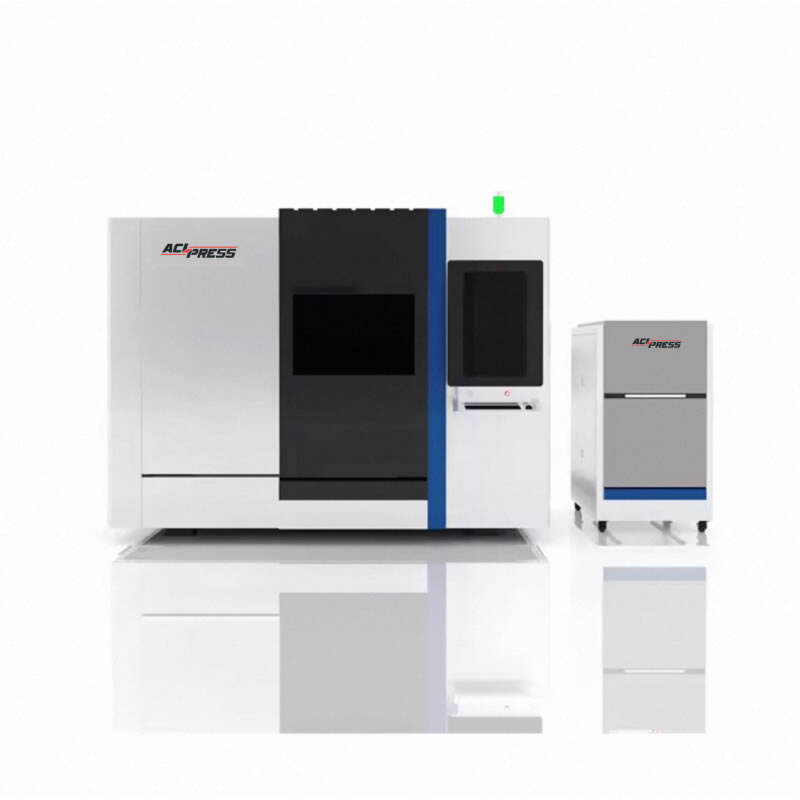

ACLPRESS a substantial production capacity due to its ducting systems which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.

ACLPRESS ducting systems exceptional processing and capability to customise products. It is well-versed in the specifics of the bending of sheet metal which allows it to provide customers optimal solutions built on production drawings specifications, needs, and current conditions to help them achieve meeting their goals in business.

ACLPRESS is actively involved in the steel bending business for more than 20 years. With extensive production and sales knowledge, we can help clients in addressing issues in a broad range of product applications. Our ducting systems provides round-the-clock technical assistance, 24 hours a day providing prompt and top-quality service to our customers.

ACLPRESS is not just home to the ducting systems of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.