Do you want to bend metal into shapes? If you are, you’ll need a specialized tool called a punch die. Punch dies are also specialized tools that help in shaping the metal accurately and precisely. These structures form metal components that are used in a variety of jobs in numerous fields. Here's an example: in the manufacturing process for cars, airplane, electronics/display items, and many more items we see in our dayto-day life, punch dies (etc.) are frequently used.

A punch die is a piece of industrial equipment that helps a punch shape metal. These are made with very strong materials such as carbide or high-speed steel. The elements make punch dies tough and sustainable. Punch die or punching die — creates holes, indentations, or other shapes in metal. They are found in many items, such as car components, aeroplanes, even door handles.

Punch dies come in various shapes and sizes. Now, each punch die is meant to do a specific job. For instance, there are round dies that create round holes, and square dies that punch square shapes. Every die is designed to guide you in forming the metal a particular course. In most industries, it is crucial to have metal projects that are incredibly detailed and accurate when you use the appropriate punch die for your job.

Good-quality punch dies are really important. ACL punch dies are manufactured from high quality materials. This also makes them long-lasting even with extensive usage for work. Well-made punching dies are durable all the while so you can use them for a longer span of time without changing them. Not only can you accomplish more with this; it also aids you in saving money on tools for the future.

Do you wish to do something special and unique with your punch dies? At ACL, we can create custom punch dies tailored just for you! And you work with us to design exactly the punch die you want that is going to form your metal exactly the way you want it to be formed. So you can have designs that are specific to your products and different from what everyone else is producing.

To create these custom designs we use special computer programs known as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). At this stage, our engineers work with these programs to ensure the design meets your specification exactly. They leave no stone unturned so that you know your final product will only be exactly what you envisioned. That’s how you can be sure that your product will stand out and be unique as our punch dies are customized according to your needs.

Punch dies are significant tools that can assist you in making your job faster and more productive. ACL punch dies are built using only the highest-grade materials allowing you to work for long hours. Our punch dies allow you to devote less time to fixing problems and more time making quality parts. That is pretty crucial in any production process.

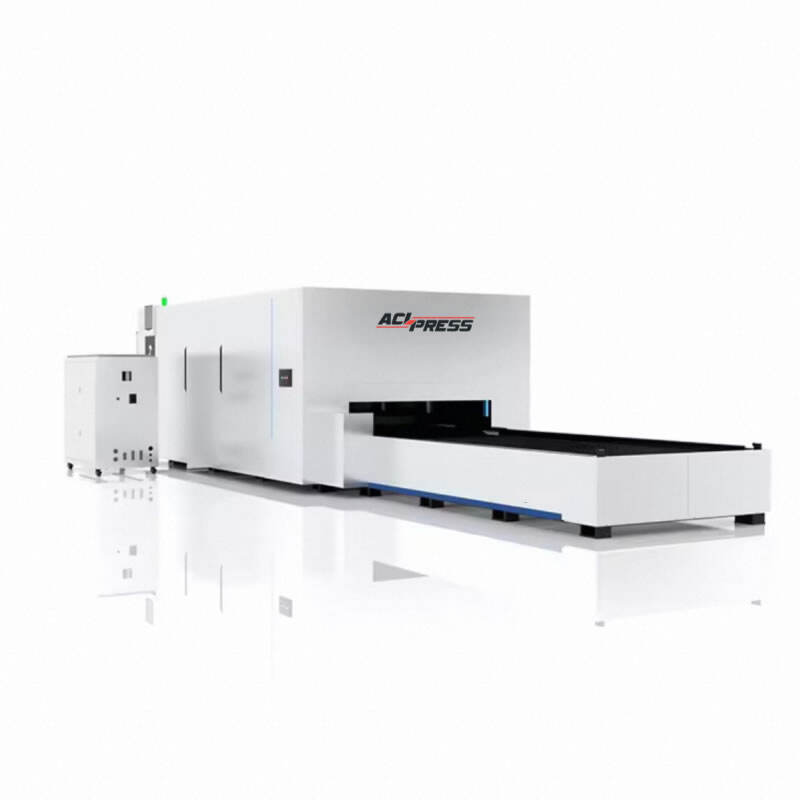

ACLPRESS has a large range of high-precision equipment that can process punch dies for press, as well with a range of inspection tools that find problems with the product and ensure its reliability. Additionally, we offer comprehensive after-sales support.

ACLPRESS boasts a large production capacity with numerous CNC machine tools including a CNC Gantry machining center CNC four-axis machining centers and CNC precise grinding machines. Additionally it a punch dies for press workshop to treat various spare parts quickly and accurately. Furthermore it houses a debugging centre is specifically designed to ensure fulfillment of orders from customers and the precise fulfillment of their requirements.

punch dies for press offers exceptional processing and product customization capabilities. ACLPRESS is highly knowledgeable of the specifics of sheet metal bending, which allows it to provide customers with the most efficient solutions based on their production drawings, needs, and conditions.

ACLPRESS has been active in the steel metal bending industry for over 20 years. We have punch dies for press in sales and production, and we can assist customers in addressing and solve issues in numerous product types. Our team of experts provides round-the clock technical support 7/24 to ensure speedy and high quality service delivery.