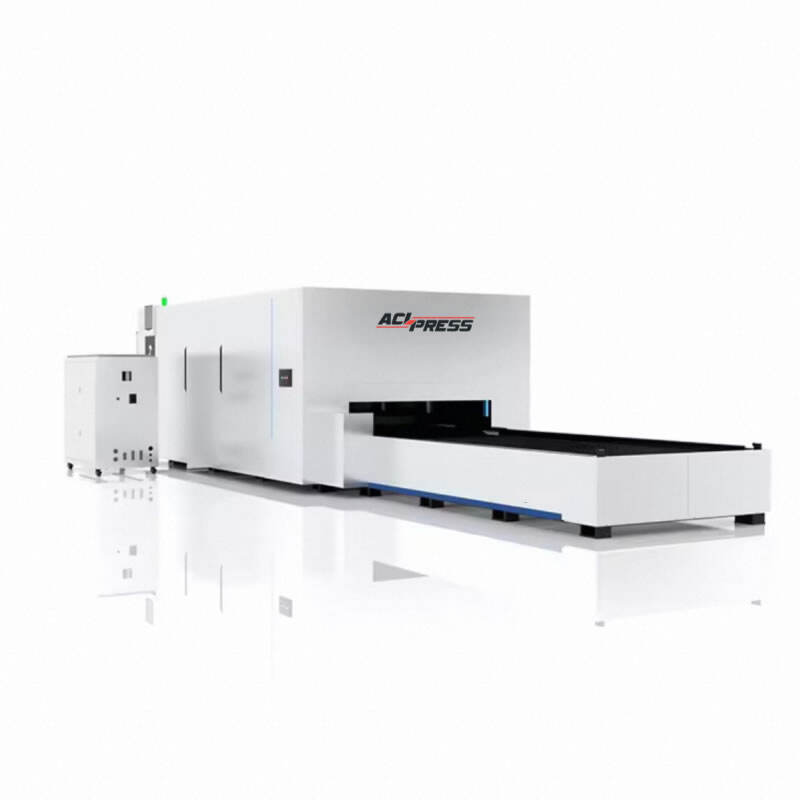

Metal bending requires precision, and not all bend operations are built the same. That’s where the Punching Machine comes into play. Whether you’re forming sheet metal for aircraft or heavy machinery, our press brake tooling punches provide a perfect bend every time! Decades of work in the industry has taught us how important having dependable machinery is for metal workers. From tough materials to versatility options, our press brake punches are engineered to provide you with the exact requirements of your application. ACL press brake punches The world of ACL Take a closer look at what we can offer.

We at ACL take great satisfaction with the accuracy engineering of our press brake punch. Every punch is engineered to deliver accurate and repeatable bends, which frees you up to create complex shapes in your metalwork. As a team of skilled tradespeople, we direct our attention to each component design of the punch and consider all components for proper material selection. This precision ensures our press brake punches will provide the exact performance and dependability you need for your metal bending application.

There is no question of durability when it comes to our metalworking machine tooling & we let that speak for itself. Constructed of high quality materials for long-lasting use, our punches can be used on anything from paper and cardstock to chipboard, leather, plastic, and more. This longevity guarantees not only the effectiveness of your manufacturing operations, but also saves you time and money for cost-reward investment in the long run. You can always depend on a quality performance from an ACL press brake punch, project after project.

This doesn't fit in a press brake die holder, but there is always the next size up, or weld or modify to suit your particular job either way it's great for many uses!

Whether your material is aluminum, stainless steel, or carbon steel, our press brake punches take the hit and keep on bending. Our punches are made to efficiently and economically withstand long hours of use with your existing machine, increasing the life of the machine. Our punches allow you to work with thin sheets, as well as thick plates and reinforce these in all thicknesses and sizes up - they are suitable for a wide range of applications from various industries. Whatever the type of metal bending on your agenda, when you request an ACL press brake punch to do the work it gets done both fast and right.

Quality is at the heart of everything we do here at ACL, including our press brake punches. Every punch is tested and inspected for its size, shape, and cutting quality. From rounding to shaping and forming, our punches will provide the desired results every time. With an ACL Press Brake, your final product is made to your exacting requirements using nothing but top-quality tooling and opening unlimited possibilities of different tools that can be inserted into an ACL press brake punch.

Your Metal Bending Project is Unique. At ACL, we realize every metal bending project is unique and offer custom-sized press brake punch options to meet your exacting needs. If you require a custom size, shape, or style, our experienced team can engineer a die set to match your specific requirements. But with ACL, you don’t have to accept one size fits all – our punches were made to fit your specific metal bending needs. When it comes to metalworking, we understand how critical your requirements are and will continue working smart to meet all of your needs by providing the services necessary for you to work smarter.

ACLPRESS is not just home to the press brake punch of precision equipment for the processing of press brakes but also various precision inspecting tools to spot defects in the product, and ensure reliability and stability. We also offer a comprehensive after-sales support.

ACLPRESS is actively involved in the steel metal bending industry for more than press brake punch. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

ACLPRESS boasts a press brake punch capability which includes a wide range of CNC machine tools such as a CNC Gantry machining center CNC 4-axis machining centers as well as CNC precision grinding machines Additionally it a heat treatment workshop processes various spare parts quickly and accurately In addition it houses a debugging centre is specifically designed to ensure the completion of customer orders as well as the precise fulfillment of their requirements

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans press brake punch, requirements, and other specifications.