Hello, young readers! Today we are going to know about a special and powerful machine named hydraulic press brake machine . This incredible machine is used to bend sheets of steel and similar items by exerting great force. So let’s investigate how it works and why it’s so crucial in factories where metal is molded and shaped.

The term pump — that's inside a hydraulic bending machine. This pump forces hydraulic fluid into another part, known as a piston. The piston that receives the fluid pushes down on the metal sheet. This forceful pressure causes the metal to twist to the form required. Due to this massive force, these machines can also fold metal sheets to a considerable thickness, which helps workers fabricate strong and durable industrial products.

Hydraulic bending machines are not only powerful, but are also driven by computer control in some cases. This is referred to as computer numerical control, or CNC. It enables programming of the machines to bend metal into special shapes and patterns with extremely high precision. This is why these machines are so useful in factories where countless pieces of metal are shaped and formed each day. Good bending techniques lead companies to manufacture higher-quality products.

One more benefit of bending dies for hydraulic presss is that they allow workers to complete their works in a much shorter period. Previously, there were no such machines, and metal workers had to bend metal by hand, or use weaker, machinery to bend metal, often take a long time and very strenuous work. It was exhausting to shape metal without powerful machines.

Now, with the advent of hydraulic bending machines, we can quickly and easily bend sheets of metal. This enables laborers to produce more goods during a shorter period. Workers can also remain safer and rest easier in place of work by ameliorating the efficiency and speed of the work. Since there is less physical strain, it allows them to focus better on their tasks as well.

One such prominent feature is the durability of hydraulic bending machines. These are built to take a beating, and many will run for years without requiring much in the way of repairs or maintenance. Their durability makes them a top investment for any company that wants to save money in the long run. This allows the company to divert resources into creating more product than spending it on repairs when machines break.

ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines ACL: Your Partner for Hydraulic Machines

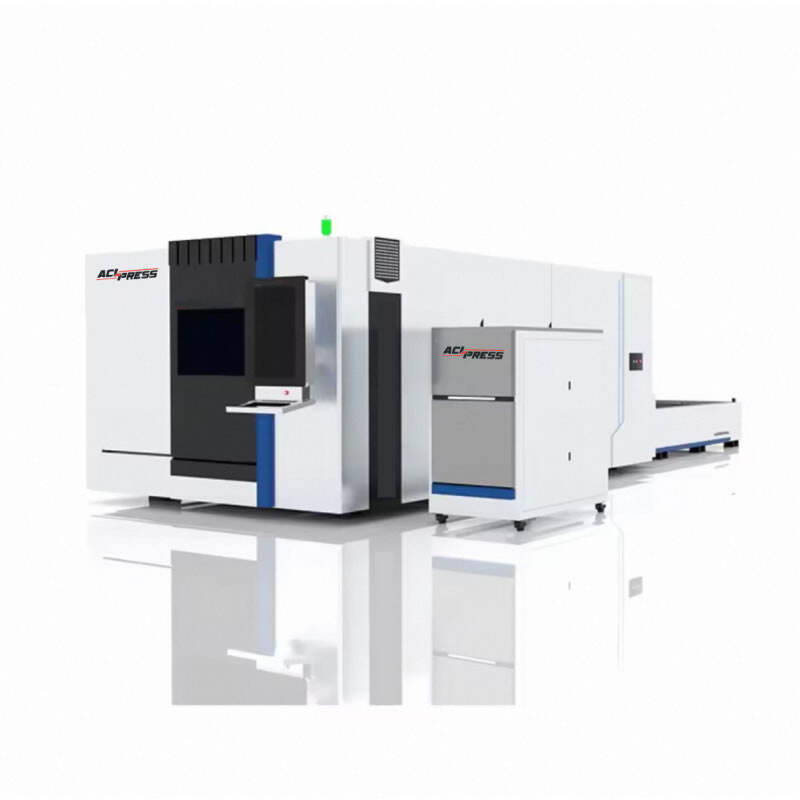

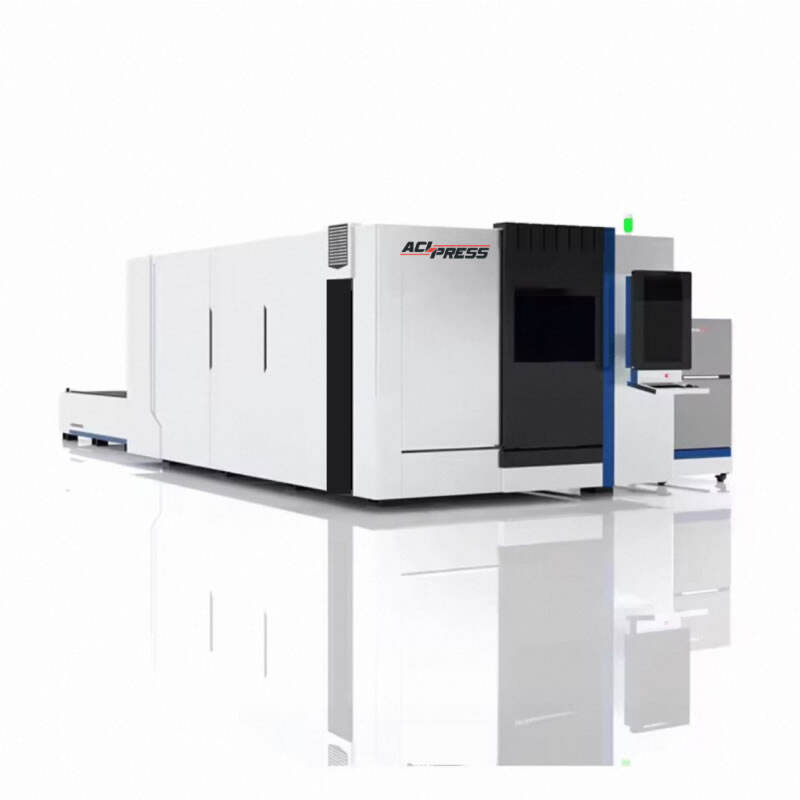

ACLPRESS hydraulic bending machine not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS is actively involved in the field of steel bending for over 20 years. With hydraulic bending machine and sales knowledge, we can help our customers in resolving problems in a range of applications for our products. Furthermore, our technical staff provides 24/7 technical support, seven days a week, ensuring prompt and high-quality support to our customers.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans hydraulic bending machine, requirements, and other specifications.

ACLPRESS a substantial production capacity due to its hydraulic bending machine which include a CNC gantry machine CNC 4-axis machines and CNC precision grinders. Additionally it a heat treatment workshop which handles various spare parts efficiently and accurately. The facility also houses a debugging centre ensures orders placed by customers are delivered on time and precisely.