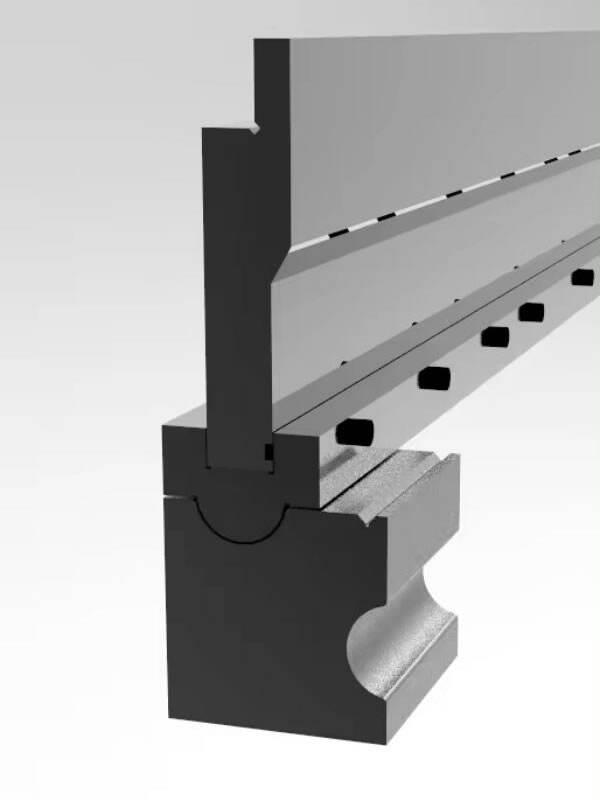

Some characteristics of Press Brake Tools

Press Brake Tools are mainly used for bending metal sheets and have the following characteristics:

High precision: Press Brake Tools usually have high manufacturing accuracy, which can ensure the precision of the bending angle and shape of the metal sheet during the processing. Especially in mass production, precision requirements are particularly important.

Strong durability: The Press Brake Tool is generally made of high-strength steel or alloy steel, which can withstand high-intensity pressure and friction, so its durability is strong and its service life is long.

Diversity and Customization: The design and manufacturing of bending machine molds can be customized according to the specific needs of customers, adapting to plates of different thicknesses, widths, and materials. Common types of molds include V-shaped molds, U-shaped molds, angle molds, etc.

High efficiency: The design of the bending machine mold can make the bending process more efficient, especially in the application of CNC bending machines, where the mold can work together with the machine to improve production efficiency.

Improving surface quality: A well-designed bending machine mold can reduce the deformation and scratches that occur during the bending process of the sheet metal, thereby improving the surface quality of the processed parts.

Multifunctionality: Modern Press Brake Tools can adapt to various complex processing needs, including multi angle and multi material bending, not limited to ordinary metal plates, but also applicable to materials such as stainless steel and aluminum alloy.

Recommended Products

Hot News

-

A Guide to Eliminating Laser Cut Burr and Slag

2024-05-16

-

Performances of CNC press brake machine

2024-05-24

-

How to tell and choose torsion axis press brake machine and electro-hydraulic CNC press brake machine

2024-06-20

-

Mastering Metal Bends: The Indispensable Press Brake Machine

2025-02-08

-

Shearing Machine Maintenance Tips to Extend Equipment Lifespan

2025-02-08

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR