One of the major things to consider while buying a bending machine is its price. The price tag of a bending machine can vary depending on the machine(s) type and quality. This guide will explore the various factors that dictate the cost of a bending machine and discuss how to find a machine that you can afford. When reviewing the cost of various bending machine, consider the requirements of your business and how much money you have. For example, a small business that does not produce much may just need a manual bending machine while a larger business that makes high volume may require a hydraulic or CNC bending machine.

Price of bending machine can vary due to several factors, including the size, capacity, and features. Larger machines that can tackle more work with greater features usually have a higher price tag than the small, basic machines. The price can change for the sheet metal bending machine depending on the brand. Certain brands are regarded as much better and more reliable, and tend to cost more. And the level of automation and precision of the machine itself can also affect the price.

Other factors that may impact the price include the materials to build the machine, the intricacy of its design and the technology it utilizes. And all these must be considered while selecting a steel sheet bending machine for your business.

When searching for an economical machine, don’t forget to consider the initial cost of the metal bending machine as well as downstream costs, such as maintenance and repairs, in the long run. So, through these considerations, you can find a suitable machine according to your budget and needs.

Although this coming to the price of a bending machine, understanding its quality is likewise to be taken into consideration. A more expensive steel bending machine may have faster speeds, greater precision, and higher longevity and will save you time or money and can keep your business running in the long run.

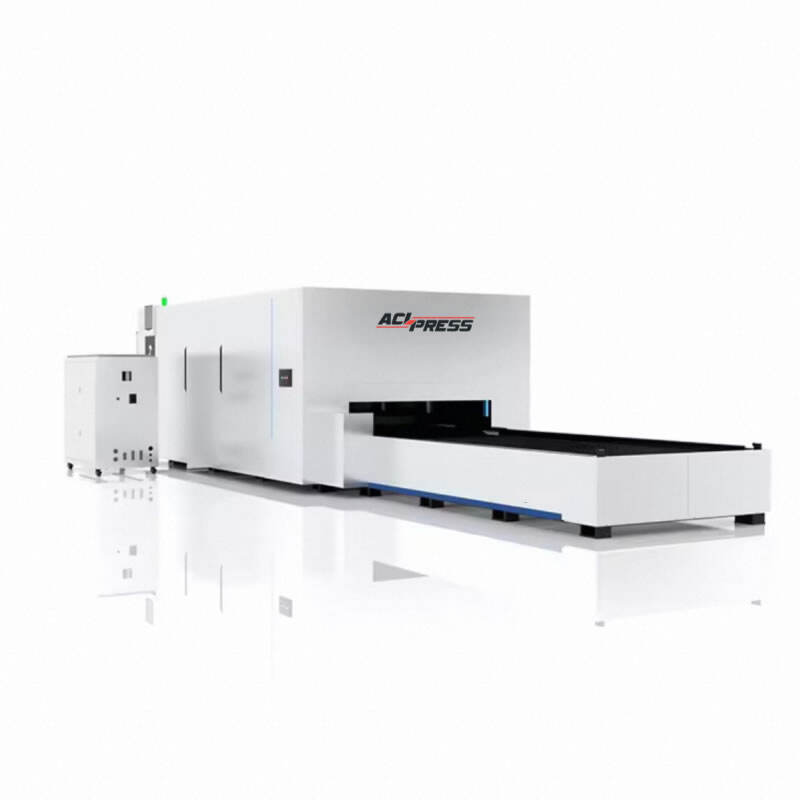

ACLPRESS Bending machine price not only an extensive range of high-precision equipment for the processing of press brakes but also various precision inspection tools to identify product issues, ensuring product quality and stability. We also offer a comprehensive after-sales service.

ACLPRESS has exceptional capabilities in processing and customizing products. ACLPRESS is well-versed in the particulars of sheet metal bends, which allows it to offer customers the most efficient solutions in line with their production plans Bending machine price, requirements, and other specifications.

ACLPRESS is actively involved in the steel metal bending industry for more than Bending machine price. With a wealth of sales and production experience, we can aid customers with resolving problems across a variety of product applications. Our team of experts provides 24 hours of technical assistance to ensure quick and high quality service delivery.

Bending machine price a large production capacity thanks to its CNC machines like a CNC Gantry Machine CNC 4-axis machines and CNC precision grinders. Moreover it operates its heat treatment workshop can treat various spare parts quickly and accurately. It also houses a debugging center makes sure the orders of customers are fulfilled punctually and accurately.